Improve profitability on every label

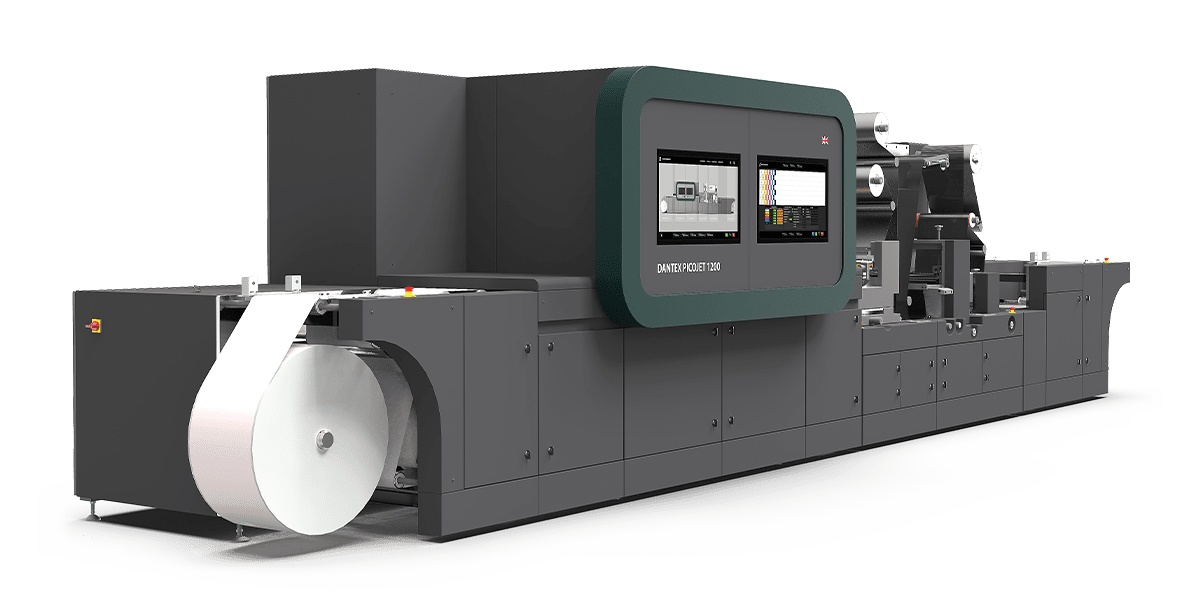

Whether you’re considering digital for short run, long run, or both, with Pico by Dantex you can have a highly productive, affordable label printing solution to meet your demanding production requirements, both now and in the future. No minimum quantity, no speciality substrates, no pre-coating and super-fast turnaround – with superb quality results.

SUPERWHITE & DECOTACTILE

Passage unique, Haute Opacité

PicoJet features SuperWhite® technology which is capable of producing a white ink opacity up to 92% in a single pass, making it the highest opacity inkjet white available on the market.

Stand out from the crowd

DecoTactile, is used to create a range of high-quality embellishments to give enhanced detail and vibrancy, such as raised tactile finishes and textures. High-build capabilities to give a digitally embossed luxury finish at low cost.

- Highest opacity inkjet white available.

- Passage unique.

- Jusqu'à 92% d'opacité.

- High quality bright white.

- Defined stable dot shape.

- No colour inter-mixing.

- Luxury finishes.

- DecoTactile print effects.

- No loss of speed.

Couleurs haute fidélitéOrange, Violet et Vert

Pico offre maintenant 3 nouvelles options de couleurs additionnelles : Orange, Violet & Vert.

Our press range already achieves above 91% of the Pantone range, but is now capable of an extended colour gamut – 96% Pantone colours at a Delta E of 3 and below.

- 3 New additional colour options.

- 96% colour gamut.

- No loss of speed.

- Greater print quality.

- Excellent colour accuracy.

- Photo-realistic images.

- Future-proofing additional colours.

- Dantex formulated inks.

- Bespoke colour profiling.

INTER COLOUR PINNING

and Final CURE

LED UV curing is ideal for the UV Inkjet market.

Dantex’s innovative inter-colour pinning technology places pinning lamps between colours to stabilize the ink, reducing the spread of the ink on synthetic substrates or diving in of ink on absorbent materials, such as uncoated papers.

A UV LED lamp’s life is around 20,000 hours. 10x longer than traditional lamps and output very little heat and no ozone.

- Control of dot gain.

- Intensity (pinning) control.

- Reduced ink spread.

- Low voltage.

- High colour accuracy.

- Superb colour consistency.

- Low heat impact.

- Eco-friendly.

- Fully adjustable.

Advanced INLINE FINISHING

Every Pico press in the range is available as a reel-to-reel printing platform.

Allowing you to utilise existing offline finishing systems, or they can be designed in a variety of hybrid configurations.

Inline flexo options offer a multitude of embellishments from spot and flood coat varnishing to spot colours and cold foiling. Self-wound and pre-wound laminates can be applied, and the full rotary die station, along with edge trim and slit modules, means you can have applicator-ready labels coming off the PicoJet every day of the week.

- Pre and Post print exo stations.

- LED and ARC cure options.

- Full rotary die station.

- Easy load die trolley system.

- No need for lifting equipment.

- Pre and self-would lamination.

- Edge trim.

- Razor and shear slit options.

- Cold foiling and embellishments.

ADVANCED COLOUR MANAGEMENT

We have strengthened Pico’s software capabilities.

Now our GIS (Global Inkjet Systems) & Esko’s DFE (Digital Front-end) together with our print head technology enhances digital print for packaging making this the complete solution from print job creation to the optimisation of print quality through precise print head control.

Esko’s DFE software allows the user to see the process colour values of any given Pantone, which can be altered by as little as 0.1%.

- Easy to use and efficient.

- Precise print head control.

- Controlled job flow.

- Stores parameters & configurations

- Edit Pantones.

- Create bespoke colours.

- Easy use step and repeat function.

- Full colour VDP.

Request a demo

Why not see Pico technology for yourself?

Book a virtual or an in-person demonstration for a full overview,

or to see particular features in action.

We look forward to showing you what the press can do!